3D Printing – The Train

- The 3D Model and 3D Print

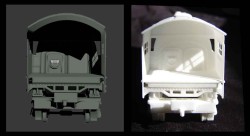

- Model vs Print

- Model vs Print

- Model vs Print

- Model vs Print

- Flexible Print

- Print Grain

- Strong Print

I decided to explore this 3D printing thing I had been hearing so much about.

I’ve had some experience with 3D modeling programs, though the true purpose of this experiment was to see what 3D printing was capable of at present, and for that I would want a 3D model with a finer level of precision and detail than I was likely to model in the allotted time for this experiment.

So I headed over to free3Dmodels.com and downloaded this exquisitely rendered model of a classic locomotive. Modeled down to individual bolts and pipe fittings. If 3D printing could do this model justice I would be truly impressed.

I decided to get quotes from two companies: i.materialize.com and 3dworknet.com both of whom allow you to upload a 3D model, choose a printing material, and they will print and ship the finished 3D Print to you for a reasonable price.

I was recommended both sites from a professional modeler who has used both services saying iMaterialize produced very hi quality work, and 3Dworknet could actually print very economically using a processes of 3D printing utilizing ordinary typing paper.

So I uploaded the model and asked for quotes for the 3D Train model printed at a total length of 8 inches. There are size limitations in 3D printing, but at 8 inches this wasn’t going to push the limits of either of these companies limitations both of which offer prints up to (16 inches).

I received an email from 3Dworkent saying the model was too detailed to attempt the economical paper process as the tolerances in that material are not greater the (mm), however they could print the job in polyamide the same strong economical plastic resin I had requested from iMaterialize.

iMaterializes website says they will produce 3D prints in material such as Gold or Silver or Titanium, by first printing the model in wax and then using the lost wax method to cast the model in the metal of your choice. The prices for this service were much higher than I was going to invest in this experiment, primarily because of the material. But I did ask if I could order the wax print directly, and I was told that was not possible because they couldn’t guarantee it would survive unbroken through shipping.

So now 2 companies quoting the same model in the same polyamide material.

iMaterialize quote: $79

3DWorknet: 295 Euros

I decided to see what iMaterialze could do…. and i must say I was impressed.

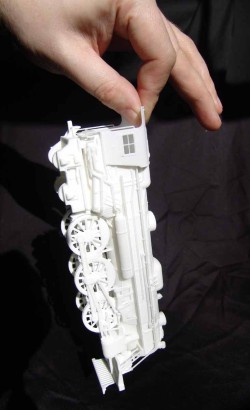

In about 2 weeks I received in the mail this model.

Upon close inspection there is a noticeably striation that is a common characteristic of 3D printed models, that is now more distracting than the dots one might see at a photo printed from an inkjet printer, but this does not detract from what I would consider a finely detailed 3D Print.

The model has a good weight and feels quite strong. I’m not sure how it would fair if dropped to the floor especially in the thin spots. But with normal handling even the thin spots feel surprisingly sturdy.

But hows the fine detail?

Let’s take a look at those bolts and pipe fittings.

The floating window pane is quite impressive, really not much thicker than a few hairs, and one might expect them to break off the moment they were touched, but they stay put and even bend slightly under light pressure, but do not break.

The floating pipes lining the sides of the train are also not fragile either and another impressive spot.

Under the wheels of the train are very fine lines that in the model are almost unnoticeable, about a hair in width. On the left side there seems to be a printing error causing it to have broken slightly… still it is impressive to see the level of precision capable in this process.

But what about those bolts that looked like some of the trickiest detail to attempt. At first they are difficult to find on the all white print because they are so small, but sure enough they’re there clear as day testing the resolution limits of the printer at this size.

Overall, I would say I am quite impressed for my first testing of the 3D Printing process, and for the price and high quality I would absolutely use iMaterialize again.